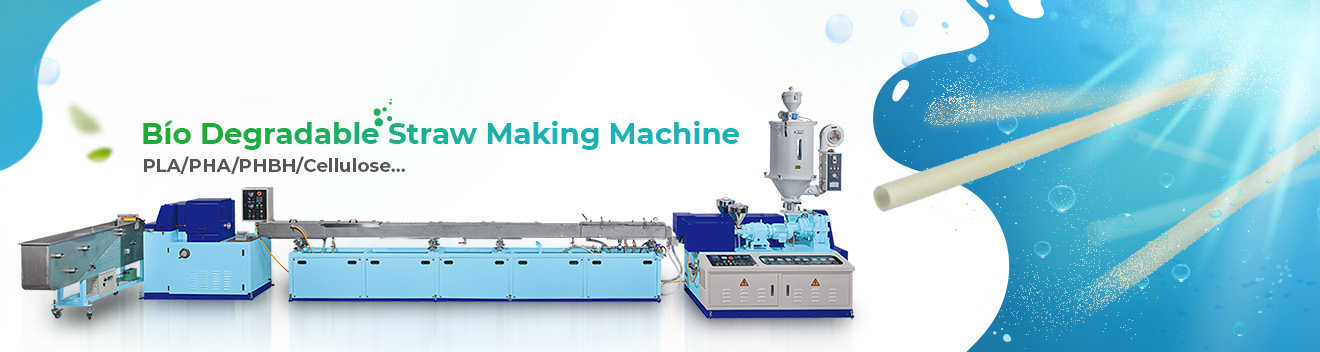

JS 336S PVC SHRINKABLE FILM PRODUCTION EQUIPMENT

PVC HEAT SHRINKABLE FILM MAKING MACHINE (Heater tank, for making shrinkable packaging film)

.jpg)

FEATURES AND CONSTRUCTION :

PVC Shrinkable file offer many excellent benefits, such as glossiness, high transparency, durability, water resistance and easy control of shrinkage. They have been applied to a wide variety of product packaging, such as foodstuff, beverage bottles, sporting goods, etc.

For over 20 years, Jumbo Steel has dedicated itself to the research of production technology for PVC shrinkable film. We have made great improvements in product prescription and machine performance, upgrading the quality and efficiency of PVC shrinkable films.We have a strong background and engineering experience for whole-plant planning and equipment supply. Jumbo Steel PVC shrinkable film production equipment has been sold worldide, and has earned a reputation for its superior machine and outstanding production know-how.

In addition to supplying the most dependable machinery, we also place emphasis on the technological support and complete production upgrades. This allows our customers to start up or resume production very quickly.

Jumbo Steel has a proven tradition of pursuing excellence and improving the PVC Shrinkable Film industry, and it will continue to develop its engineering capabilities and raise industry standards.

SPECIFICATIONS :

| MODEL | JS 333S | JS 334S | JS 336S | JS 336S | ||

|---|---|---|---|---|---|---|

| Feature | Material | P.V.C. | ||||

| Film Thickness Range | mm | 0.02 - 0.06 | 0.02 - 0.06 | 0.02 - 0.06 | 0.02 - 0.06 | |

| Layflat Width Range | mm | 50 - 200 | 70 - 300 | 150 - 500 | 200 - 700 | |

| Extruding Output Range | kg/hr | 4 - 10 | 8 - 15 | 15 - 30 | 20 - 50 | |

| Extruder | Screw dia. | m/m Ø | 35 | 45 | 55 | 65 |

| Screw L/D | 30 : 1 | 25 : 1 | 25 : 1 | 25 : 1 | ||

| Drining Motor | hp | VS 7 1/2 | VS 10 | VS 20 | VS 25 | |

| Heater Capacity | kw | 8.4 | 6.9 | 10.6 | 15 | |

| Automatic Thermo-Controller | set | 5 | 6 | 6 | 6 | |

| Cylinder Cooling Equip | Air Blower x 3 sets | |||||

| Dies | Dia. | m/m Ø | 30, 40 | 40, 60 | 60, 100 | 80, 120 |

| Heater Capacity | kw | 2.4, 2.4 | 2.4, 2.6 | 2.6, 3 | 2.9, 3.5 | |

| Take up & Inflation Unit (water tank type) |

First Take Up Roller | Ømm x mm | Ø138 x 250 | Ø138 x 300 | Ø165 x 450 | Ø165 x 600 |

| Heating Tank | set | 1 | 1 | 1 | 1 | |

| Motor | hp | AC1/2x1+AC1x1 with inverter | AC1/2x1+AC1x1 with inverter | AC1x1+AC2x1 with inverter | AC1x1+AC2x1 with inverter | |

| Take Up Roller | mm Øx mm | 140 x 250 | 140 x 450 | 165 x 660 | 165 x 860 | |

| Take Up Speed Range | m/min | 10 - 40 | 10 - 40 | 10 - 40 | 10 - 40 | |

| Heater | kw | 11.3 | 13.5 | 18.6 | 23.9 | |

| Automatic Thermo-Controller | set | 1 | 1 | 1 | 1 | |

| Water Ring | set | 1 | 1 | 1 | 1 | |

| First Take Up | set | 1 | 1 | 1 | 1 | |

| Winding Unit | Winding Capacity | mm Øx mm | 400 x 200 | 400 x 400 | 400 x 600 | 400 x 800 |

| Dc Torque Motor | hp | 1/2 HP x 2 | 1/2 HP x 3 | 1/2 HP x 2, 1 HP x 1 |

1/2 HP x 2, 1 HP x 1 |

|

| Other | Air Compressor | hp | 1 | 1 | 2 | 2 |

| Total Electricity | kw | 30.3 | 34.5 | 52.8 | 68.5 | |

| Dimension L x W x H | m | 4.4x1.4x2.4 | 5.1x1.85x3.45 | 4.6x1.9x3.7 | 6.4x2.1x3.9 | |

| Machine Weight | ton | 1.8 | 2.4 | 2.7 | 3.8 | |

* All specifications and design characteristics are subject to change without prior notice.